Spinal disc replacement has revolutionized the treatment of degenerative disc disease by offering a motion-preserving alternative to traditional spinal fusion. A critical factor in the success of these procedures is the materials used in the artificial discs. Dr. Larry Davidson, a leader in spinal surgery, recognizes that nanotechnology, with its ability to manipulate materials at the molecular level, is now transforming spinal disc replacement. By enhancing material properties such as durability, biocompatibility and integration, nanotechnology is paving the way for more effective and long-lasting implants.

Understanding Nanotechnology in Medical Applications

Nanotechnology involves the design and manipulation of materials at the nanoscale, typically measuring less than 100 nanometers. At this scale, materials exhibit unique properties that can be leveraged to enhance their performance in medical applications. In spinal disc replacement, nanotechnology allows for the creation of implants that closely mimic the natural structure and function of biological tissues, improving patient outcomes and reducing complications.

How Nanotechnology Enhances Spinal Disc Replacement Materials

Biocompatibility and Tissue Integration

One of the primary challenges in spinal disc replacement is ensuring the artificial disc integrates seamlessly with the patient’s natural spinal tissues. Nanotechnology enables the development of surface coatings that enhance biocompatibility, promoting better integration with bone and soft tissues. For example, nanostructured titanium and other nanomaterials can be engineered to encourage cell attachment and bone growth, reducing the risk of implant rejection or loosening.

Durability and Wear Resistance

Artificial discs must withstand significant mechanical stress over time. Nanotechnology enhances the durability of implant materials by creating surfaces that resist wear and abrasion. Nanostructured polymers and ceramics are particularly effective at improving the longevity of spinal disc implants, reducing the likelihood of material degradation and the need for revision surgeries.

Mimicking Natural Disc Properties

The natural spinal disc is a complex structure that combines strength, flexibility and shock absorption. Nanotechnology allows for the design of materials that replicate these properties more closely than traditional materials. Nanocomposite materials, for instance, can provide the flexibility needed for motion preservation while maintaining the strength required to support spinal loads.

Advancements in Nanotechnology for Spinal Implants

- Nanostructured Coatings

Nanostructured coatings are applied to the surface of artificial discs to improve their interaction with surrounding tissues. These coatings can release bioactive molecules that encourage bone growth and reduce inflammation, creating a more favorable environment for the implant.

Additionally, antimicrobial nanocoating can minimize the risk of postoperative infections.

- Smart Nanomaterials

Smart nanomaterials are being developed to respond to changes in the spinal environment, such as temperature or pressure. These materials can adapt dynamically, providing enhanced support and reducing stress on adjacent spinal segments. For example, shape-memory polymers embedded with nanoparticles can adjust their stiffness based on the mechanical demands of the spine.

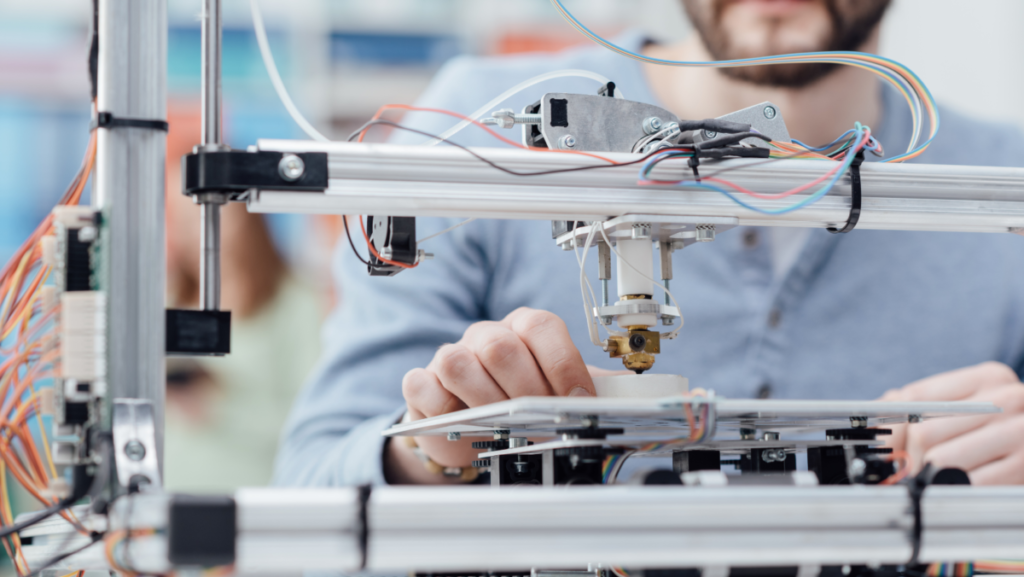

- 3D Printing with Nanomaterials

Another significant advancement is the integration of nanotechnology with 3D printing. Using nanomaterials in 3D-printed implants allows for the creation of highly customized artificial discs tailored to each patient’s anatomy. These personalized implants improve fit, function and overall surgical outcomes.

Benefits of Nanotechnology in Spinal Disc Replacement

The incorporation of nanotechnology into spinal disc replacement materials offers numerous benefits:

- Enhanced Integration: Improved biocompatibility and tissue integration reduce complications such as implant rejection and loosening.

- Increased Longevity: Nanostructured materials exhibit superior wear resistance, extending the lifespan of artificial discs.

- Better Functionality: Materials designed with nanotechnology more closely replicate the natural properties of spinal discs, preserving motion and reducing stress on adjacent segments.

- Reduced Infection Risk: Antimicrobial nanocoating lowers the likelihood of postoperative infections, improving patient safety.

Challenges in Implementing Nanotechnology

Despite its potential, integrating nanotechnology into spinal disc replacement materials is not without challenges. High production costs and complex manufacturing processes can limit accessibility and affordability for some patients. Additionally, the long-term effects of certain nanomaterials on the body are not yet fully understood, requiring more research to ensure safety and efficacy.

Regulatory hurdles also pose challenges, as nanotechnology-based implants must undergo rigorous testing to meet safety and quality standards. However, ongoing advancements in this field are gradually overcoming these barriers, making nanotechnology more viable in clinical practice.

Clinical Applications and Success Stories

Nanotechnology-enhanced spinal disc implants are already showing promise in clinical settings. Patients receiving implants with nanostructured coatings or nanocomposite materials report faster recovery times and fewer complications. For example, nanostructured titanium implants have demonstrated improved bone integration, leading to greater implant stability and reduced pain.

In one case, a patient with severe degenerative disc disease underwent surgery with a nanotechnology-based artificial disc. The implant’s biocompatible coating facilitated rapid tissue integration, resulting in a quicker return to normal activities and improved mobility.

The Future of Nanotechnology in Spinal Disc Replacement

Further advancements in nanotechnology lie in the future of spinal disc replacement. Researchers are exploring the use of nanoscale robotics for real-time monitoring and maintenance of implants. These tiny devices could detect early signs of wear or misalignment and prolong the implant’s functionality.

Dr. Larry Davidson mentions, “When considering the possibility of spinal disc replacement (artificial disc surgery), the key point is proper patient selection. This adage is true with respects to all aspects of spinal surgery. The preservation of motion remains one of the key advantages of this type of surgery.” As nanotechnology continues to advance, it holds the potential to further refine artificial disc designs, enhancing motion preservation and long-term success rates.

Additionally, the combination of nanotechnology with regenerative medicine offers exciting possibilities. For example, nanomaterials could be used to deliver stem cells or growth factors directly to the implant site, promoting natural tissue regeneration and further enhancing the success of spinal disc replacement.

Nanotechnology is transforming the landscape of spinal disc replacement, offering innovative solutions to longstanding challenges. By enhancing biocompatibility, durability and functionality, nanotechnology is improving the effectiveness and longevity of artificial discs, leading to better outcomes for patients. While challenges such as cost and regulatory approval remain, ongoing research and development are making these advanced materials increasingly accessible.

As nanotechnology continues to evolve, its integration into spinal disc replacement will unlock new possibilities, enabling more personalized, effective and durable treatments for patients with degenerative spinal conditions. For those seeking a lasting solution to chronic back pain, nanotechnology represents a promising path forward.